Mfmea Template

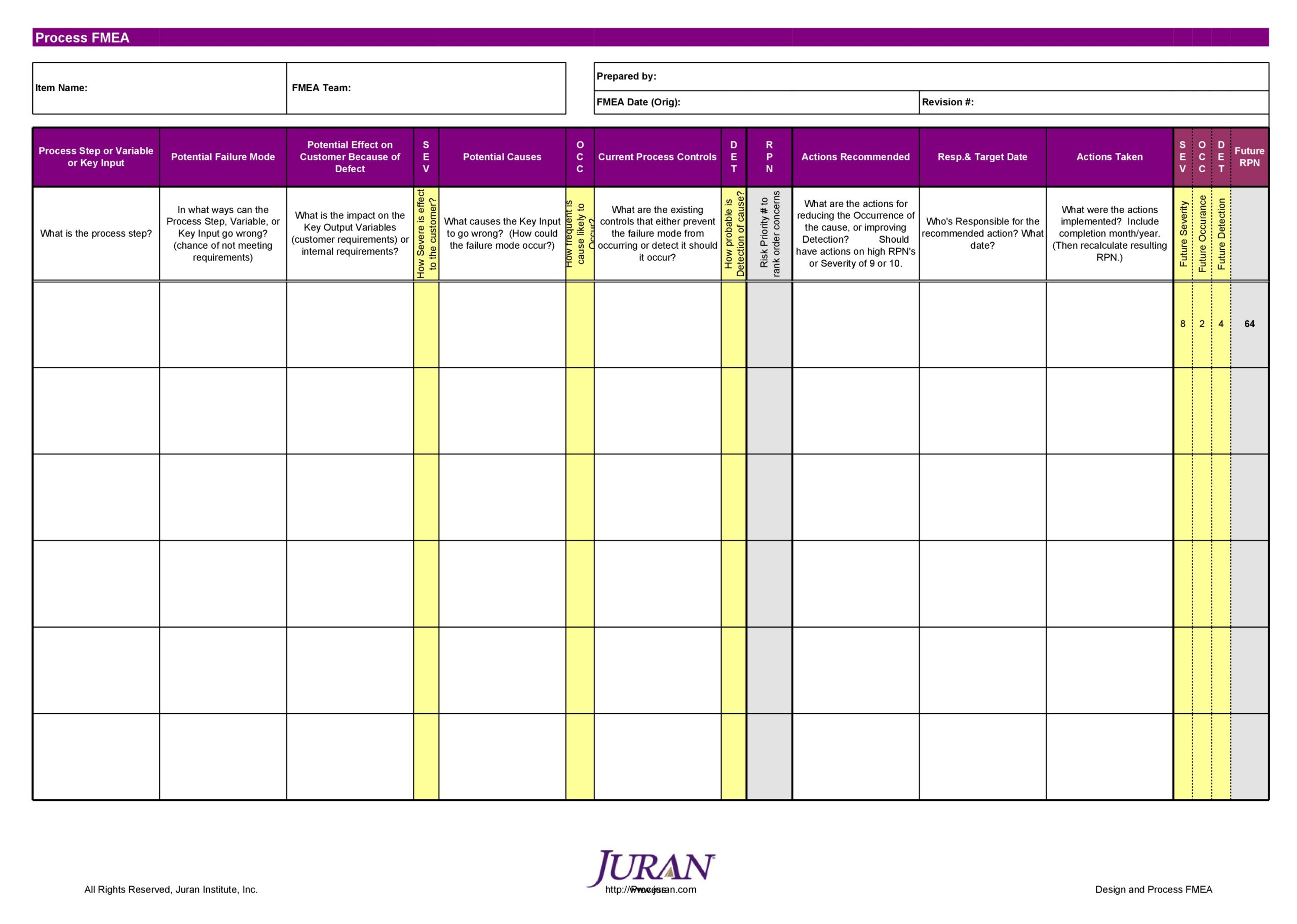

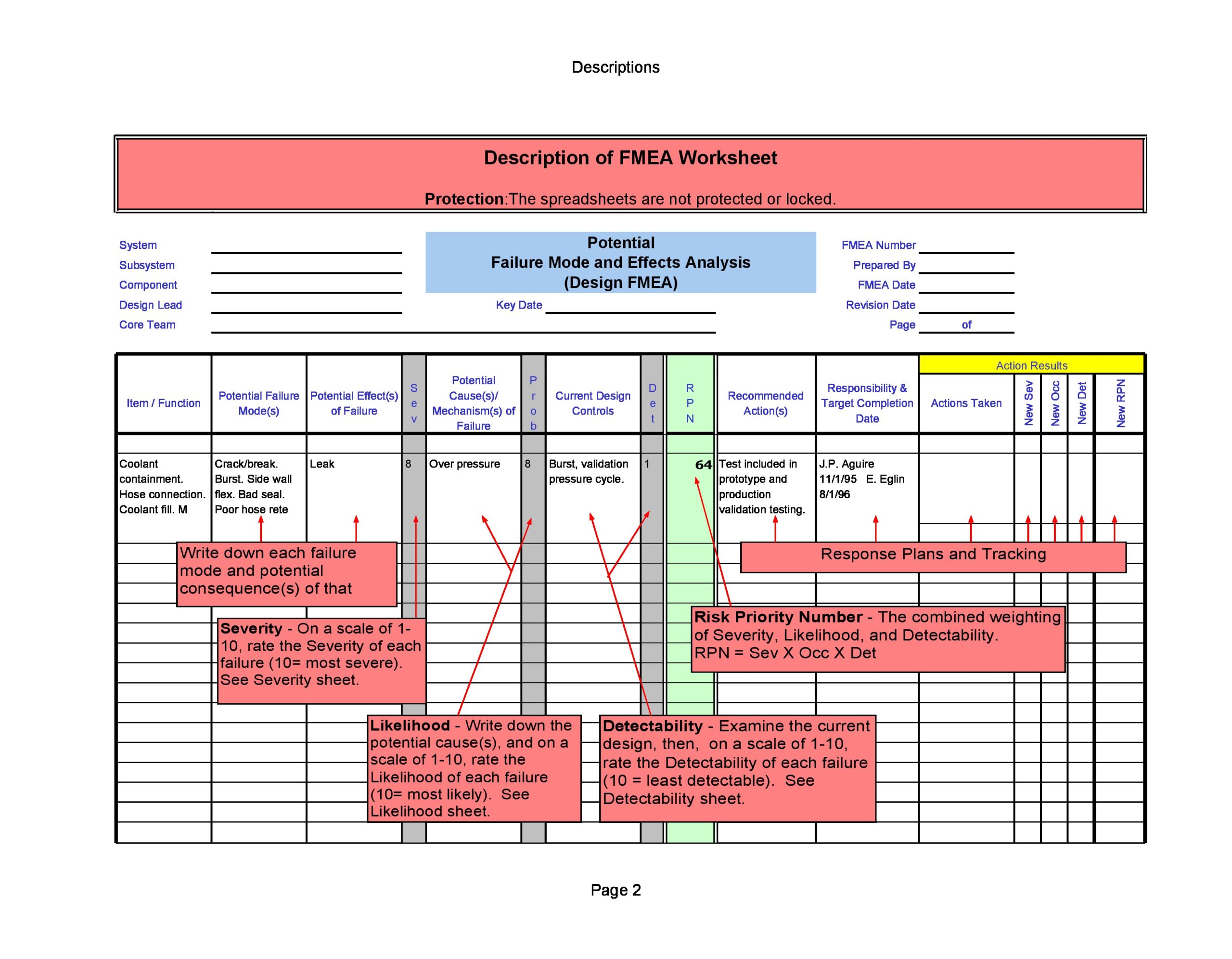

Mfmea Template - Assembly level ” fixtures/tools, material handling, drives. Both template editions can be found in the doe. Web a typical mfmea follows a hierarchical model in that it divides the machine into subsystems, assemblies, and lowest replaceable units. Web there are two main types of fmea: Web why you should try miro for fmea analysis. Design of products and services, (dfmea) and the processes that make or deliver them (pfmea) An fmea template aims to identify potential problems in a process, product or design and prevent their adverse effects on customers. A summary list of the recommended actions identified during the analysis. Fmea analyzes potential failures using three criteria: Failure modes are the individual ways where problems can occur within a process. Interfaces with other systems or components; This is an effective tool for companies to analyze their services, processes, and products. Failure mode and effects analysis is a systematic way to anticipate problems, and to reduce risks in both: Web machinery fmea is a methodical approach used for identifying risks associated with machinery and equipment failure. Worksheets that focus on specific. This is an effective tool for companies to analyze their services, processes, and products. Assembly level ” fixtures/tools, material handling, drives. Web whether you’re a green belt or black belt, these lean six sigma templates can support your dmaic process. Templates are free to download and customize. Prioritize product or process deficiencies visually to gain the best results and satisfy. Web failure modes and effects analysis (fmea) is a systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures, in order to identify the parts of the process that are most in need of change. Fmea analyzes potential failures using three criteria: Web failure modes &. Web fmea means failure mode and effects analysis. Hfmea worksheets, steps 1 &. Monitor the implementation and effectiveness of corrective actions with the use of this. Looking for a free fmea template that can help you conduct a failure mode and effects analysis easier and faster right inside excel. The report is based on the sample analysis provided in the. Save an fmea analysis as a template; Automatically generate reports from checklists; Web a typical mfmea follows a hierarchical model in that it divides the machine into subsystems, assemblies, and lowest replaceable units. The template allows you to customize the. Looking for a free fmea template that can help you conduct a failure mode and effects analysis easier and faster. Fmea analyzes potential failures using three criteria: Save an fmea analysis as a template; Failure modes are the individual ways where problems can occur within a process. Monitor the implementation and effectiveness of corrective actions with the use of this. Both template editions can be found in the doe. Web failure modes and effects analysis (fmea) is a systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures, in order to identify the parts of the process that are most in need of change. Web begun in the 1940s by the u.s. Web excellence through. You’re in the right place. What could possibly go wrong? Web the machinery fmea (mfmea) spreadsheet report in the sae j1739 reporting format. Interfaces with other systems or components; Web machinery fmea is a methodical approach used for identifying risks associated with machinery and equipment failure. Web fmea means failure mode and effects analysis. Web about values mapped from an fmea template to asset strategy template; Both template editions can be found in the doe. Web machinery fmea is a methodical approach used for identifying risks associated with machinery and equipment failure. Web whether you’re a green belt or black belt, these lean six sigma templates. Apply asset template to multiple assets; The template allows you to customize the. Web fmea template fmea tools for failure mode effects analysis why do we need an fmea? Both template editions can be found in the doe. Use the apply template builder; Failure mode and effects analysis is a systematic way to anticipate problems, and to reduce risks in both: Web failure modes and effects analysis (fmea) is a systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures, in order to identify the parts of the process that are most in need of change. Promote an fmea template to asm; Both template editions can be found in the doe. Failure modes are the individual ways where problems can occur within a process. Rating criteria and classifications rating criteria and classifications Web machine failure modes and effects analysis is conventional way of applying fmea methodology to custom equipment and machinery design. This analysis needs a team to work together closely to identify issues on their business processes and products to rank potential effects and create an effective action plan. The report is based on the sample analysis provided in the sae j1739 guidelines, on page 45. Web the machinery fmea (mfmea) spreadsheet report in the sae j1739 reporting format. Apply asset template to multiple assets; The purpose of the mfmea is to increase reliability of the machinery, reduce time to repair and add prevention techniques, such as diagnostics. Web about values mapped from an fmea template to asset strategy template; Web a typical mfmea follows a hierarchical model in that it divides the machine into subsystems, assemblies, and lowest replaceable units. A summary list of the recommended actions identified during the analysis. Web there are two main types of fmea: Web machinery fmea is a methodical approach used for identifying risks associated with machinery and equipment failure. Assembly level ” fixtures/tools, material handling, drives. Web fmea means failure mode and effects analysis. Web fmea template fmea tools for failure mode effects analysis why do we need an fmea? Both template editions can be found in the doe. This analysis needs a team to work together closely to identify issues on their business processes and products to rank potential effects and create an effective action plan. Occurrence (failure cause and frequency) severity (impact of the failure) detection (likelihood of failure detection) Web the machinery fmea (mfmea) spreadsheet report in the sae j1739 reporting format. The purpose of the mfmea is to increase reliability of the machinery, reduce time to repair and add prevention techniques, such as diagnostics. Templates are free to download and customize. Assembly level ” fixtures/tools, material handling, drives. You’re in the right place. Monitor the implementation and effectiveness of corrective actions with the use of this. Design of products and services, (dfmea) and the processes that make or deliver them (pfmea) Web the basics of healthcare failure mode and effect analysis. Web failure modes and effects analysis (fmea) is a systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures, in order to identify the parts of the process that are most in need of change. The template allows you to customize the. Hfmea worksheets, steps 1 &. Fmea analyzes potential failures using three criteria: Web excellence through quality | asqAvoid Failure When Using Failure Modes and Effects Analysis (FMEA)

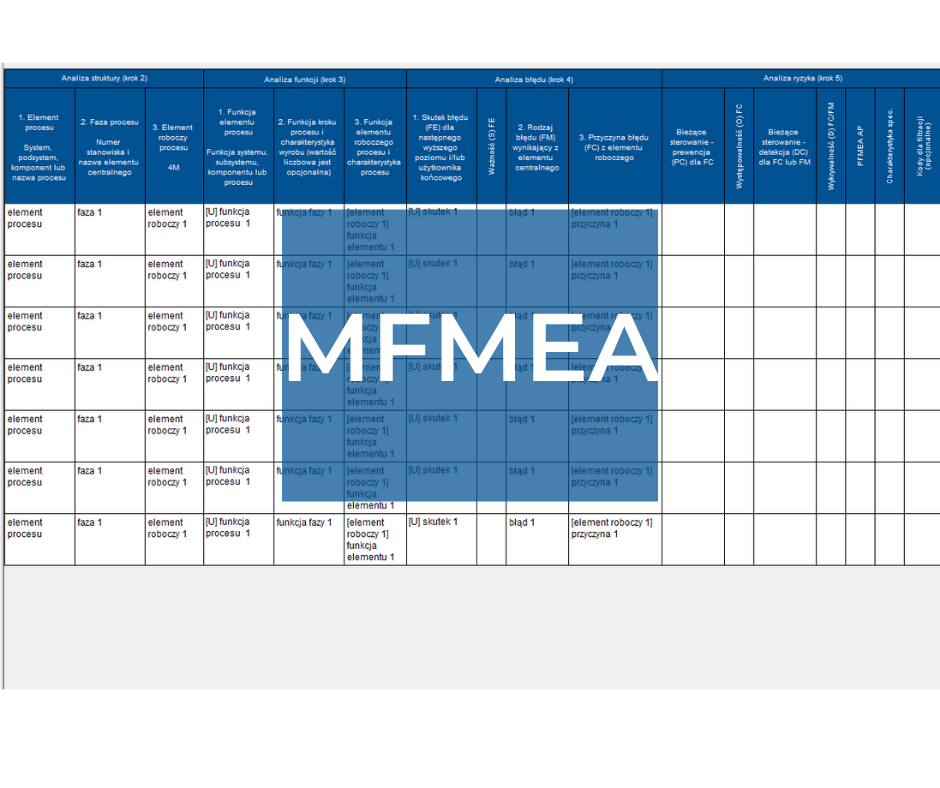

Machinery FMEA (MFMEA)

MFMEA Occurrence

30 Useful FMEA Examples (Free Templates) TemplateArchive

5 Fmea Examples For Excel Powerpoint And Pdf Images and Photos finder

MFMEA Detection

Machinery FMEA Machinery Failure Mode & Effects Analysis QualityOne

AIAG Potential Failure Mode and Effects Analysis for Tooling

30 Useful FMEA Examples (Free Templates) TemplateArchive

MFMEA analiza przyczyn i skutków wad wyposażenia produkcyjnego

Web Machine Failure Modes And Effects Analysis Is Conventional Way Of Applying Fmea Methodology To Custom Equipment And Machinery Design.

Fmea Is A Method For Identifying Potential Problems And Prioritizing Them So That You Can Begin To Tackle Or Mitigate Them.

Worksheets That Focus On Specific Steps:

Then, It Helps You Take Steps To Mitigate Or Reduce Their Negative Outcomes.

Related Post: